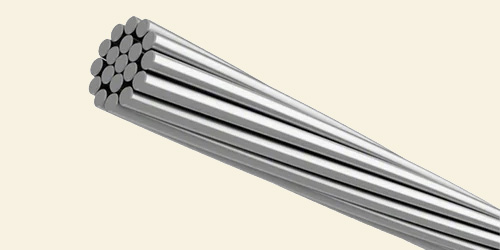

It is made from Aluminium - Magnesium - Silicon alloy of high electricals conductiviting (0.6-0.9%) and silicon (0.5-0.9%) to give it better mechanical properties after treatment, These conductors are generally made out of Aluminium Alloy 6201 (IACS is 54%). It has a better corrosion resistance and better strength to weight ration and improved electrical conductivity than ACSR on equal diameter basis.

| Sr. No. | Nom. AI Area mm | Standing & Wire Dia in mm | Approx over all Dia in mm | Approx Mass in Kg/ Kg | Description | Approx Calculated Breaking Load (KN) |

|---|---|---|---|---|---|---|

| 1 | 15 | 3/2.5 | 5.39 | 40.15 | 2.3040 | 4.33 |

| 2 | 22 | 7/2.00 | 6.00 | 60.16 | 1.5410 | 6.45 |

| 3 | 34 | 7/2.50 | 7.50 | 94.00 | 0.9900 | 10.11 |

| 4 | 55 | 7/3.15 | 9.45 | 149.20 | 0.6210 | 16.30 |

| 5 | 80 | 7/3.81 | 11.43 | 218.26 | 0.4250 | 23.41 |

| 6 | 100 | 7/4.26 | 12.78 | 272.86 | 0.3390 | 29.26 |

| 7 | 125 | 19/2.89 | 14.45 | 342.51 | 0.2735 | 36.64 |

| 8 | 148 | 19/3.15 | 15.75 | 406.91 | 0.2298 | 43.50 |

| 9 | 173 | 19/3.40 | 17.00 | 474.02 | 0.1969 | 50.54 |

| 10 | 200 | 19/3.66 | 18.30 | 549.40 | 0.1710 | 58.66 |

| 11 | 232 | 19/3.94 | 19.70 | 636.67 | 0.1471 | 68.05 |

| 12 | 288 | 37/3.15 | 22.05 | 794.05 | 0.1182 | 84.71 |

| 13 | 346 | 37/3.45 | 24.15 | 952.56 | 0.0984 | 101.58 |

| 14 | 400 | 37/3.71 | 25.97 | 1101.63 | 0.0855 | 117.40 |

| 15 | 465 | 37/4.00 | 28.00 | 1280.50 | 0.0734 | 136.38 |

| 16 | 525 | 61/3.31 | 29.79 | 1448.39 | 0.0651 | 146.03 |

| 17 | 570 | 61/3.45 | 31.05 | 1573.71 | 0.0598 | 158.66 |

| 18 | 604 | 61/3.55 | 31.95 | 1666.00 | 0.0568 | 167.99 |

| 19 | 642 | 61/3.66 | 32.94 | 1771.36 | 0.0534 | 178.43 |

| 20 | 695 | 61/3.81 | 34.29 | 1919.13 | 0.0492 | 193.25 |

| 21 | 767 | 61/4.00 | 36.00 | 2115.54 | 0.0446 | 213.01 |

It is manufactured from EC Grade Aluminium wire rods having purity of min. 99.5% of Aluminium (with IACS of 61%). It is mainly used in Urban area because the spacing is short and supports are close. These conductors are also used extensively in costal area because they have high degree corrosion resistance.

| Sr. No. | Code Name | Size AL/ Dia. (mm) | Aluminium Area mm² | Weight (Kg.) | D.C. Resistance at 20° C (Ohms/ Km.) |

|---|---|---|---|---|---|

| 1 | Gnat | 7/2.21 | 26.85 | 74 | 1.096 |

| 2 | Mosquito | 7/2.59 | 36.90 | 101 | 0.7763 |

| 3 | Lady Bird | 7/2.79 | 42.90 | 117 | 0.6689 |

| 4 | Ant | 7/3.10 | 52.77 | 145 | 0.5560 |

| 5 | Gross Hopper | 7/3.91 | 84.13 | 230 | 0.3406 |

| 6 | Wasp | 7/4.39 | 106.20 | 290 | 0.2770 |

| 7 | Special | 19/3.18 | 150.00 | 415 | 0.915 |

| 8 | Cricket | 7/5.36 | 157.90 | 432 | 0.1813 |

| 9 | Caterpillar | 19/3.53 | 185.90 | 511 | 0.1547 |

| 10 | Spider | 19/3.99 | 237.30 | 654 | 0.1244 |

| 11 | Cockroach | 19/4.22 | 265.30 | 731 | 0.1083 |

| 12 | Butterfly | 19/4.65 | 322.40 | 888 | 0.01971 |

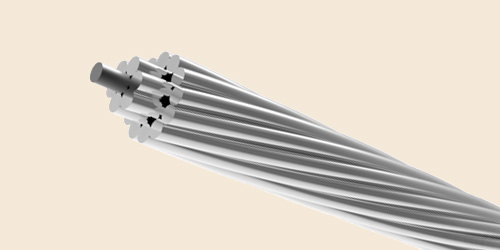

ACSR consists of a solid or stranded steel core surrounded by strands of aluminium wires. ACSR are used for river crossing, overhead ground wires, installation involving extra long spans. Against any given resistance of conductors, ACSR may be manufactured for having a wide range of tensile strength as per requirement. The principal advantage of these conductors is high tensile strength and light weight so that they are used for longer spans with less support. Due to greater diameter of ACSR a much higher corona limit can be obtained causing big advantages on high as well as on extra high voltage overheads lines.

| Sr. No. | ACSR Code Word | Cond. Area mm | Stranding & Wire Dia in mm | Calculated Sectional Area Sq. mm. | Approx Overall Dia mm | Weight Kg./Km. | Calc. Electrical Resistance at 20°C Ohms/km | Approx Catc. Breaking Load (KN) | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | Mole | 10 | 6/1.50 | 1/1.50 | 10.60 | 12.37 | 4.50 | 43 | 29 | 14 | 2.780 | 3.97 |

| 2 | Special | 18 | 6/1.95 | 1/.1.95 | 18.10 | 21.12 | 5.88 | 73 | 50 | 23 | 1.618 | 6.74 |

| 3 | Squirrel | 20 | 6/2.11 | 1/2.11 | 20.98 | 24.48 | 6.33 | 85 | 58 | 27 | 1.394 | 70.61 |

| 4 | Weasel | 30 | 6/2.59 | 1/2.59 | 31.61 | 36.88 | 7.77 | 128 | 87 | 41 | 0.929 | 11.12 |

| 5 | Rabbit | 50 | 6/3.35 | 1/3.35 | 52.88 | 61.70 | 10.05 | 214 | 145 | 69 | 0.552 | 18.25 |

| 6 | Raccoon | 80 | 6/4.09 | 1/4.09 | 78.83 | 91.97 | 12.27 | 319 | 216 | 103 | 0.371 | 26.91 |

| 7 | Dog | 100 | 6/4.72 | 7/1.57 | 105.00 | 118.50 | 14.15 | 394 | 288 | 106 | 0.279 | 32.41 |

| 8 | Wolf | 150 | 30/2.59 | 7/2.59 | 158.10 | 194.90 | 18.13 | 726 | 437 | 289 | 0.187 | 67.34 |

| 9 | Panther | 200 | 30/3.00 | 7/3.00 | 212.10 | 261.50 | 21.00 | 974 | 586 | 388 | 0.139 | 89.67 |

| 10 | Kundah | 400 | 42/3.50 | 7/1.96 | 404.10 | 425.20 | 26.88 | 1281 | 1116 | 165 | 0.073 | 88.79 |

| 11 | Zebra | 420 | 54/3.18 | 7/3.18 | 428.90 | 484.50 | 28.62 | 1621 | 1186 | 435 | 0.069 | 130.32 |

| 12 | Moose | 520 | 54/3.53 | 7/3.53 | 528.50 | 597.00 | 31.77 | 2004 | 1461 | 537 | 0.056 | 161.20 |

These are largely used for windings of transformers, LV and HV coils. Sizes are selected by customers as per their design requirements. We use high grade quality E. G. insulation kraft paper so that uniform covering and full insulation is assured.

| TECHNICAL DETAILS OF ROUND WIRE | |||

|---|---|---|---|

| Sr. No. | Area | Width | Thickness |

| 1 | 0.515-12.56 Sq. mm. | 0.81 mm (215 swg) 4 mm (85 swg) | 1.2-5 mm |

| 2 | Paper Insulation | 0.111 - 0.625 mm | |

| 3 | Packing | In wooden reels upto 20 Kg. (If required the reels may also be Packed in gunny bags) | |

| TECHNICAL DETAILS OF STRIP WIRE | |||

|---|---|---|---|

| Sr. No. | Area | Width | Thickness |

| 1 | 5-54 Sq. mm. | 4-12 mm | 1-2-5 mm (but max. width + thickness not more than 17 mm) |

| 2 | Paper Insulation | 0.111-2.125 mm | |

| 3 | Packing | In Wooden Reels up to 110 Kg. | |

Our range of super enamelled wires are available in various diameter ranging from 21 guage (0.81mm) to 35 guage (0.21mm). There are widely used in Transformers, Electrical Chokes, Exhast Fans, Air Coolers, Sewing Machines & Electrical Fittings. We have recently developed Super Enamelled Wires with polyester based varnish, which acts as a replacement of Copper Enamelled Wire in some applications.

Bare Aluminium wire are manufacturers as per customers requirement. These are widely sold to manufacturers of Cables, Winding Wires, Eyelets, Rivets, Nails, Hangers, Screws, etc.

Tubas Wire & Conductor Pvt. ltd. (TWCPL) started its operation in 2003 to manufacture value added products of aluminium.

304-A, STANDARD HOUSE,

83, M. K. MARG, MARINE LINES

MUMBAI – 400 002

+91 9322401513

tubasmumbai@gmail.com

© All Rights Reserved by Tubas Wire & Conductor Pvt. ltd.

Designed By Mirackle Solutions